To build digital a road system the current road needs to be completely re-thought.

Today a road is made of some tar and or bitumen surface, which is founded with sand and stone. The surface is hard, the road system it makes up does not support any other purpose than being a road. The cost of building, maintaining and renovating these roads are high. The road consumes energy. The road system costs money. It doesn’t generate it.

The new ways for Europe are different.

It starts with the fundament the road lies within.

The inventors of Solar Roadways had a great idea. For their prototype road of modules, they incorporated a cable corridor into the concrete base on which the road lies. It can be used as drainage for surface water or shaft to lay cables.

Why would you want a cable corridor at the sides of a road?

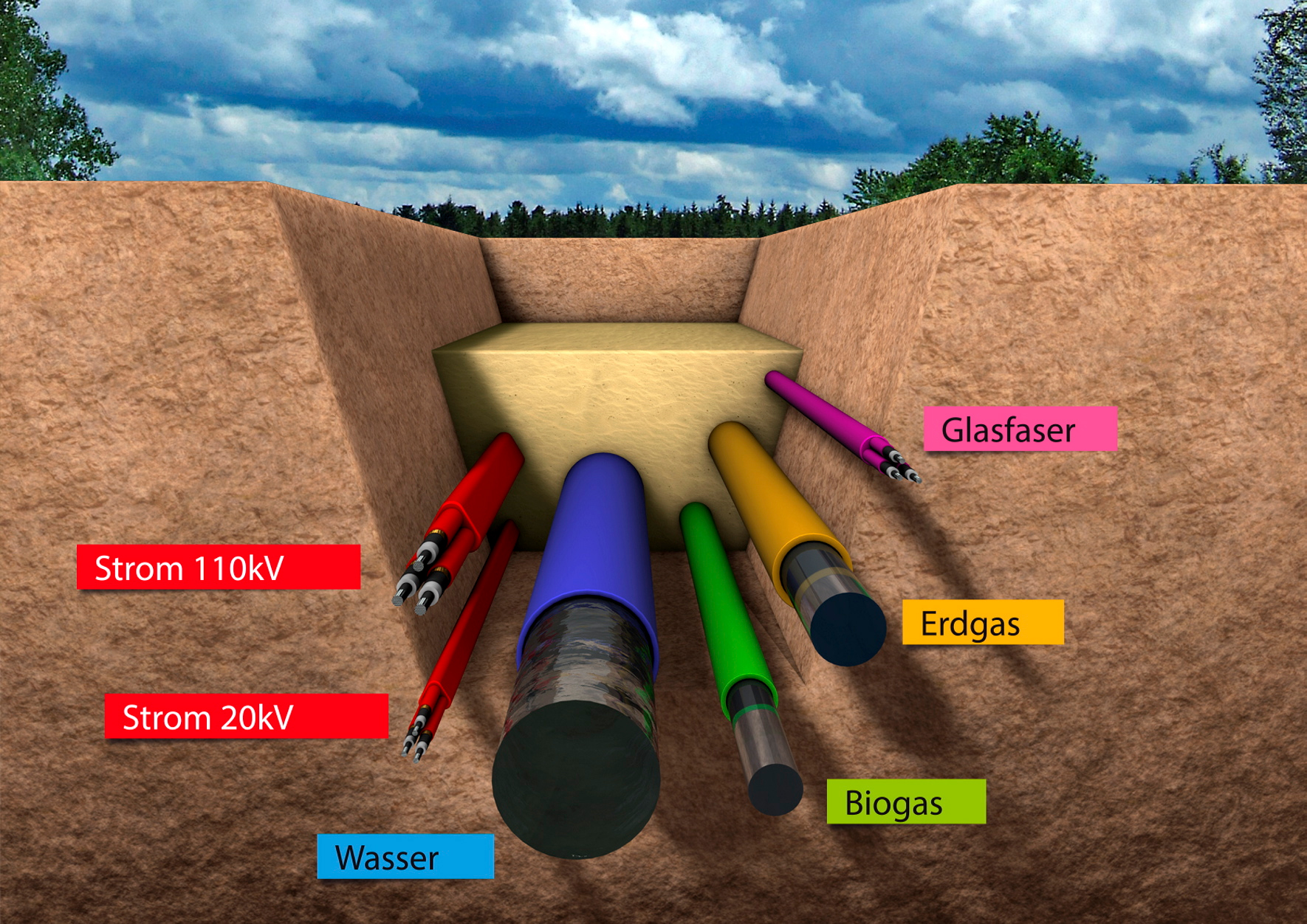

A cable corridor on the side of the road makes the fast and non-immersive laying of glass-fiber cables, electricity (high and low voltage) lines, drinking- and waste-water as well as gas pipes, their exchange and maintenance easy and cheap possible.

It would mean that we use our roads multi-functional.

They would not only provide a surface for transport and traffic, but also the possibility to carry our energy, gas and water supplies and the communication lines.

Instead of digging chambers through the environment or building dangerous pylons and transmission lines, which kill millions of birds each year the new ways for Europe use the European road net as an already existing grid and transforms it into an innovative supply network for the whole continent.

To build a road with a cable corridor or a chamber changes the design of the base. From a flat base which lies on a subgrade and a bed, the base is now extended. It get’s two side chambers to carry cables or to function as a drainage.

The second chamber is needed if the road is supposed to function as a carrier for high-voltage buried cables.

Due to the electromagnetic fields and the heat the cables carries, while transmitting the electricity, they can not be taken in the same chamber as all other cables and pipes. Instead, the high-voltage cables have to be embedded in liquid soil.

Both chambers have to have a minimum depth of 1,5m-1,7m to cause no harm to the environment above the surface and the road modules and to lay safe.

As the electromagnetism and the heat of this construct is a challenge to construction. The liquid soil solution is supported by the way and the material of which the base is build.

Poly-Care Research Technology invented a polymer concrete which is formed similar to LEGO-stones and can also be pressed in other useful forms.

These polymer concrete stones are free of cement and don’t need typical construction sand. They can be made of a diverse range of material. Some of these materials could be heat and or electromagnetism containing materials which protect the surrounding environment from the effects. One of the great innovations of Poly-Care is that their stones can be produced with a mobile production factory.

This mobile production plant can use the existing materials, which could be parts of the old recycled road.